DoE Launches Oak Ridge Institute

The next wave of innovation got a boost over the summer, when the DoE announced it was contributing $20 million to launch the Oak Ridge Institute (ORI), expanding the partnership between UT and ORNL.

US Senator Lamar Alexander and former UT president (1988–91), heralded the news, saying he believed it would lay the groundwork for the institute and partner institutions to be viewed as one of the world’s leading engineering and science alliances.

TCE is already a key partner in several successful joint UT-ORNL programs, such as the Governor’s Chairs program, the Bredesen Center for Interdisciplinary Research and Graduate Education, and the Joint Institute for Advanced Materials. The graduate programs of the Bredesen Center alone account for more than 250 doctoral students, and the two institutions share more than 250 joint faculty members, with many of both of those figures coming from the college.

A Vital Boost

Professor Aly Fathy (EECS) and Associate Dean for Academic and Student Affairs Ozlem Kilic are leading a Department of Defense-funded medical research program to develop technology to use microwaves to detect a person’s vital signs remotely.

The system, called VitalWave, was developed by UT and MaXentric. It uses ultra-wideband, micro-Doppler radar to access the vital signs of multiple users in an environment, including through obstacles.

What started as a way to detect survivors of disasters—such as in collapsed buildings following earthquakes—has evolved to include other uses, such as monitoring patients remotely during pandemics, providing feedback to athletes during competition, and combatting suicide among prison populations.

The team, which includes a mixture of graduate and undergraduate students, was awarded $300,000 through the Joint Warfighter Medical Research program, which serves to help further research related to military medicine. The US Small Business Administration’s Small Business Innovation Research program is helping develop the research.

Novel Radiation-Resistant Material Developed

Keeping nuclear power plants running requires materials that can withstand factors like radiation, pressure, and heat. With one third of Tennessee Valley Authority customers reliant on nuclear energy, improvements to these materials are of a particularly high importance to the region.

A team of joint UT and ONRL researchers including Associate Professor Yanwen Zhang, UT-ORNL Governor’s Chair for Radiation Effects on Materials William Weber, and UT-ORNL Distinguished Scientist Takeshi Egami (all of MSE) has developed a breakthrough material that helps address those concerns through the use of specific alloys.

Using different combinations of elements to fine-tune chemical complexity at the level of both electrons and atoms, the research has resulted in alloys that are much more tolerant to radiation, giving them a longer life in terms of their use in nuclear power production. The alloys are being tested at UT’s Ion Beam Materials Laboratory to further the understanding of their potential use in the development of future power plants.

Reopening to a New Normal

Much of the world is cautiously reopening as the COVID-19 pandemic continues, even as some cities and regions have still not reached their peak of new cases, much less begun to see a decline.

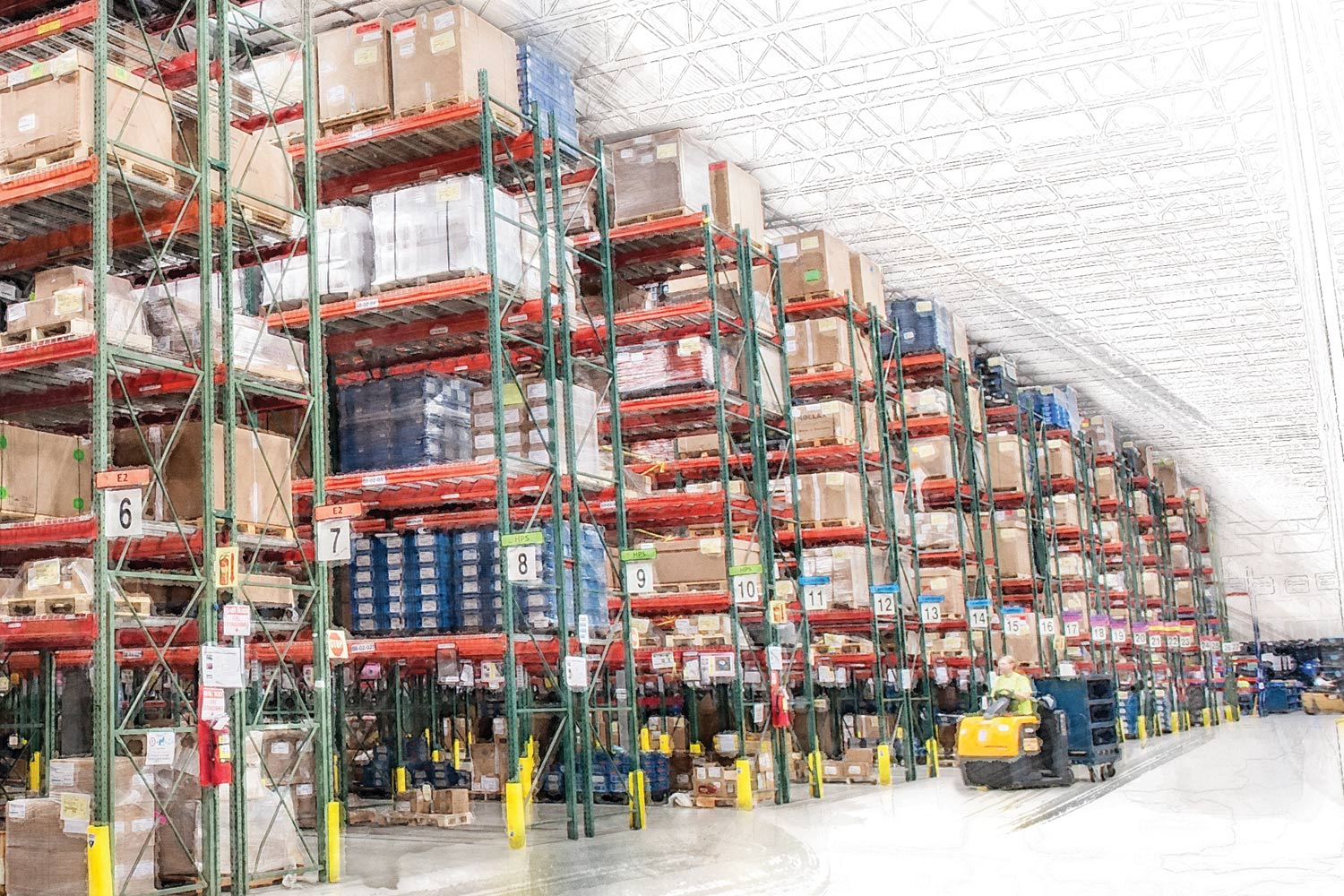

Differing laws between countries, states, and even municipalities within states can greatly affect efforts to reopen businesses, with some areas having strict quarantines while others are trying to normalize economic activity as much as possible. The disruption is hampering everything from deliveries to employee commutes.

Professor Mingzhou Jin (ISE) is closely researching how these processes are being affected and how the pandemic has exposed issues related to the resiliency of supply chains, how centralized manufacturing and distributed manufacturing processes have produced different results, how and when there has been a trade-off between being resilient versus being efficient, and how the balance between corporate profit and social welfare is being impacted.

He is a leading a team of researchers from UT’s Tickle College of Engineering, College of Nursing, the Department of Public Health in the College of Education, Health, and Human Sciences, and the UT Heath Science Center that is preparing a Leading Engineering for America’s Prosperity, Health, and Infrastructure (LEAP-HI) proposal to the National Science Foundation to further support the research.

Improving Active Shooter Outcomes

The issue of school shootings and what to do about them can be a polarizing topic, but one in need of a solution nonetheless. Associate Professor Subhadeep Chakraborty (MABE) has taken on the heavy burden presented by that challenge, coming up with a system that seeks to improve outcomes in such situations: Active Shooter Tracking and Evacuation Routing for Survival (ASTERS). The program was developed in conjunction with researchers at Iowa State.

ASTERS uses technology to track potential suspects, letting first responders and officials in the school know where the person is and where they are moving. Importantly, it also uses what it knows about the school’s layout to tell people within classrooms whether they are better off trying to leave the building, barricading in place, or move to a different space within the school.

The project is being funded by the National Science Foundation and received written support by UT police at both the Knoxville and Chattanooga campuses.

Reinforcing Morgan County

A crumbling bridge in rural Morgan County, Tennessee, will receive a high-tech upgrade thanks to the development of fiber-reinforced polymer (FRP) composite materials developed by UT researchers at IACMI—The Composites Institute.

Fred N. Peebles Professor and JIAM Chair of Excellence Dayakar Penumadu (CEE) is providing guidance and materials for the project. Critically for the county, the project came at no cost, as IACMI was eager to demonstrate the technology.

Sensors will be placed within and throughout the bridge, giving Penumadu and others valuable data that will aid future designs. Penumadu said that such data is hard to come by in newer materials like composites, and that the sensors will provide feedback for years.

FRP holds promise for upgrading aging civil infrastructure nationwide, with reduced cost and maintenance being two major advantages.