Advisory Council Role Puts Hines on Forefront of Tennessee Nuclear Energy Planning

Nuclear engineering Department Head Wes Hines shares a vital leadership role on the Tennessee Nuclear Energy Advisory Council, recently established by Tennessee Governor Bill Lee. Hines is co-chair on the council’s Education/Workforce Work Group, along with Loong Yong, president and owner of Oak Ridgebased company Spectra Tech. The committee also includes alumnus H.M. “Hash” Hashemian, president and CEO of AMS Corporation and an adjunct professor in nuclear engineering.

Lee created the council with an executive order to advance the state’s position as a national leader in nuclear energy. The initiative builds on a legacy in nuclear innovation and seeks to drive continued investment into a nuclear energy ecosystem for the future of Tennessee. The council is supported through $50 million Nuclear Fund in the state’s Fiscal Year 2023-2024 budget.

Within this work group, Hines and colleagues address expectations for the future nuclear energy workforce in the state, identifying potential gaps and forming plans to fill them as nuclear industry grows.

Vol Researchers Look to Give EV Batteries a Second-Life on the Grid

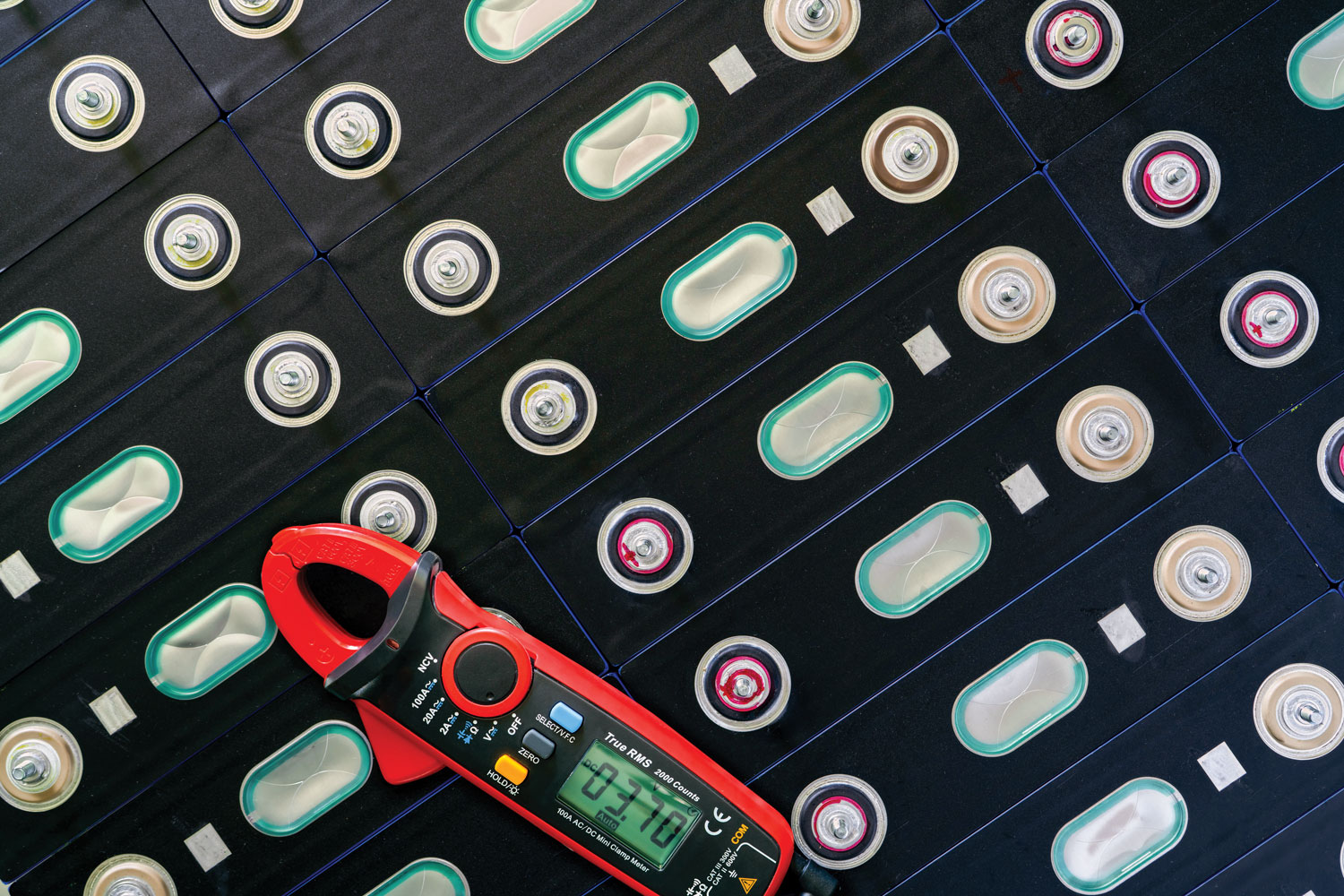

As transportation increasingly relies on electric-based systems, a challenge arises in what to do with batteries from electric vehicles (EVs) as they age. One solution is to offer them a second life once they retire from the road. The team of Kevin Bai, Leon Tolbert, and Fred Wang in EECS, are working with the Volkswagen Group of America in Chattanooga to apply second-life batteries (SLBs) from EVs to power grids—an approach that would reduce cost of both EVs and energy storage systems (ESSs).

The proposed EV SLB project would model the EV battery degradation in grid-connected applications, integrate the battery to the power grid through power electronics converters, and monitor the battery state of charge and state of health. The success of the project would help guide the industry in the proper sizing of the battery energy storage system, reduce battery recycling costs, and enhance the power grid resiliency.

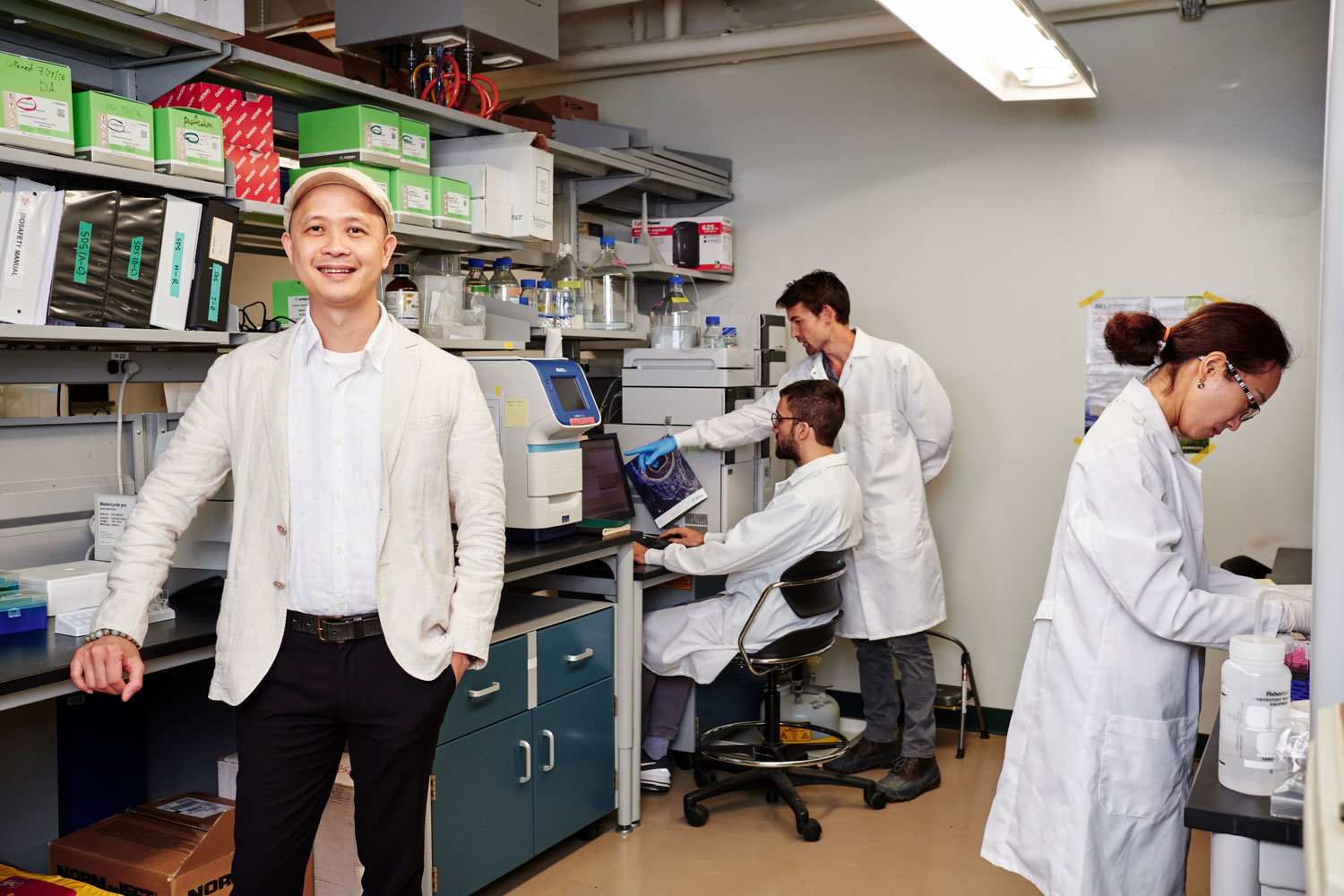

Trinh Lab’s New Yeast Strain Upcycles Stubborn Plastics

The Tennessee River is one of the most plastic-polluted rivers in the world. Most of the waste is polyolefin, a class of plastics made from fossil fuels and used for everything from grocery bags to car bumpers. CBE Professor Cong Trinh, the Ferguson Faculty Fellow in Chemical Engineering, is currently working towards creating a line of synthetic modular cells with exchangeable, “plug-and-play” genetic modules.

Trinh’s team has been looking for naturally occurring (or “wild type”) cells with the ability to digest polyolefins. Once they discover the process the wild microbes use, they can copy the corresponding DNA ‘module’ into synthetic cells to efficiently upcycle polyolefin trash.

Trinh and his team traced the digested plastic molecules through the yeasts, identifying the enzymes and key processes required to upcycle the polyolefins. With this foundation, Trinh hopes to turn the yeasts into cellular ‘factories’ that transform pollution into useful materials.

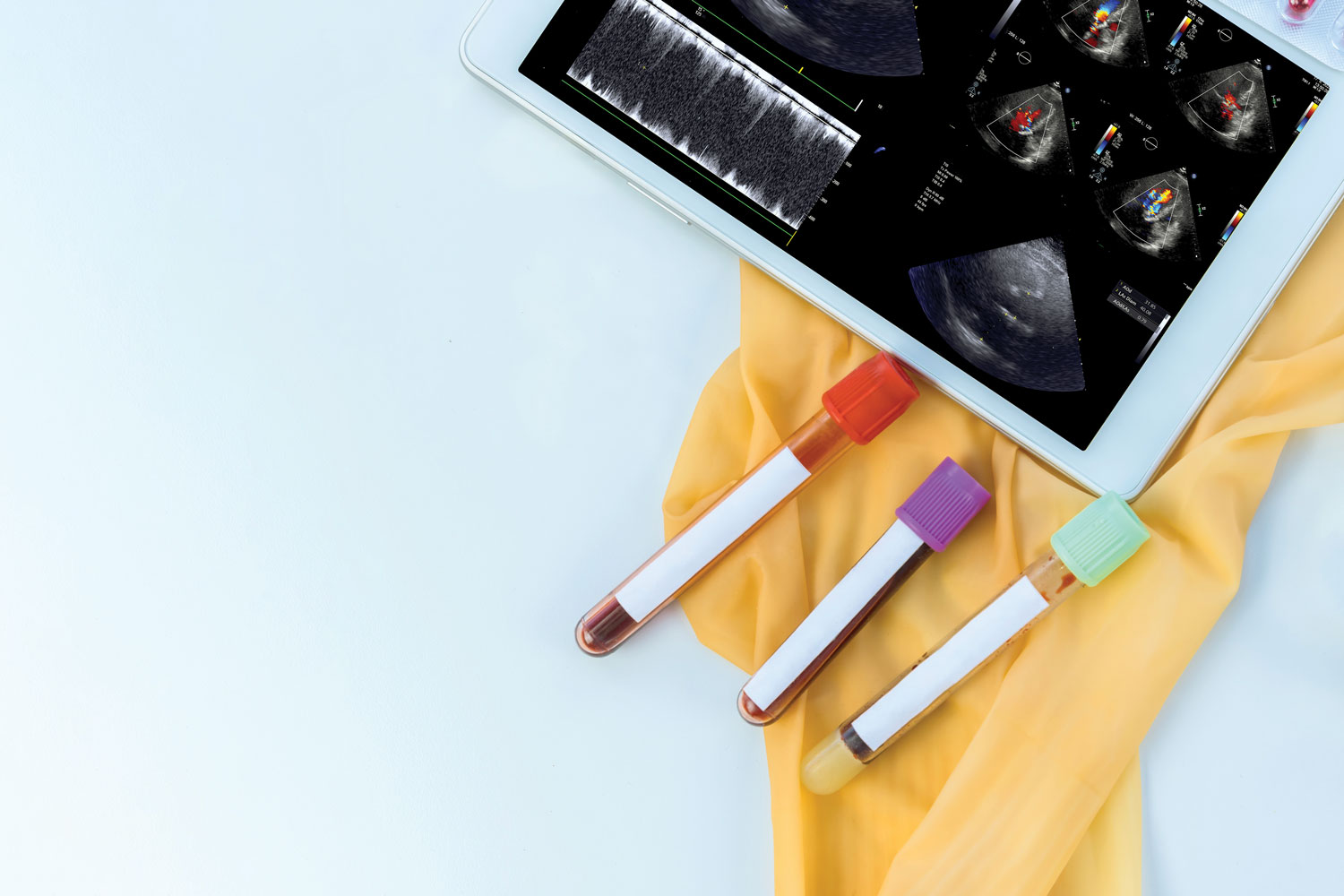

Yao Receives $1.1 Million to Create Algorithm that Personalizes Heart Surgery

Atrial fibrillation (AF) is an arrhythmia (irregular heartbeat) disorder caused by misfiring nerves in the heart. Up to 6.1 million Americans are affected by AF, but cases are on the rise. Untreated AF can lead to stroke, heart failure, and other serious complications. The condition can usually be treated with ablation, surgery; however, up to 30 percent of AF patients still experience AF after multiple ablation procedures.

This fall, Dan Doulet Early Career Assistant Professor Bing Yao’s in the Department of Industrial and Systems Engineering proposal received a four-year, $1.1 million grant from NSF, a funding initiative that promotes next generation medical technologies.

The team will construct an accurate, physics-based model of the cardiac system, then train a deep-learning AI on several types of data encountered during a cardiac patient’s diagnosis and surgery. By integrating the vast amounts of data already generated during a patient’s medical journey, Yao’s team hopes to make individualized healthcare available to every AF patient, increasing the success rate for ablation and other surgeries.

UT-ORNL Collaboration Calibrates new Possibilities for Additive Manufacturing

A collaborative effort of UT and ORNL researchers forged a 2023 R&D 100 Award for an innovative process that improves longevity for 3D-printed metal goods. Suresh Babu, UT-ORNL Governor’s Chair for Advanced Manufacturing and senior advisor for research and STEM workforce development initiatives, and Alex Plotkowski, senior staff scientist at ORNL, led the team in developing OpeN-AM, a platform for performing operando neutron (OpeN) diffraction studies of metals during additive manufacturing (AM), also known as 3D printing.

They published their results in Nature Communications. Their method provides a new pathway to tailor residual stress states and property distributions—improving fatigue life and resistance to stress-corrosion cracking—within 3D-printed components, and to qualify parts for largescale structures relevant to energy systems.Their system provides unparalleled insight into the evolution of phase transformations and stressors that occur during the additive manufacturing process. New possibilities abound in knowing how these phenomena behave.

Hattar Oversees Microscopy Advance Through International Connections

NE Associate Professor Khalid Hattar led the US contingent of an international team on a recent project to install a world-first user-adjustable pole piece (UAP) transmission electron microscope (TEM) lens. He and a team of scientists and engineers from the Ultramicroscopy Research Group at Trinity College Dublin (TCD) in Ireland, installed the lens at Sandia National Laboratories (SNL), where Hattar previously worked as a research scientist in the Center for Integrated Nanotechnologies. He is now the director of the Tennessee Ion Beam Materials Laboratory.

The installation of the lens is the result of five years of research and engineering efforts by the Dublin team, led by Assistant Professor Lewys Jones. The TIBML will stay connected to further development of these capabilities through several current contracts with SNL researchers.