Beneath the University of Tennessee campus, 11 miles of underground pipes connect a steam plant to dorms, classrooms, sports facilities, and research labs. To help ensure efficient heating of the air and water inside 150-plus buildings, Facilities Services has turned to drone technology to inspect the pipes for leaks.

By Meghan McDonald. Photography by Randall Brown.

Last spring, they partnered for the first time with the UT Institute of Geotechnology. The institute serves an educational function for students and, under the direction of Khalid Alshibli, it is expanding into an additional role—offering affordable drone-based services to the university and the local engineering community.

“Drones are a large investment, but they’re a fast way to collect data and access difficult sites,” said Alshibli, who also serves as a professor, associate department head for graduate studies, and coordinator for the Geotechnical and Materials Group. “A drone flying for two minutes might equal days of work on the ground,” he added.

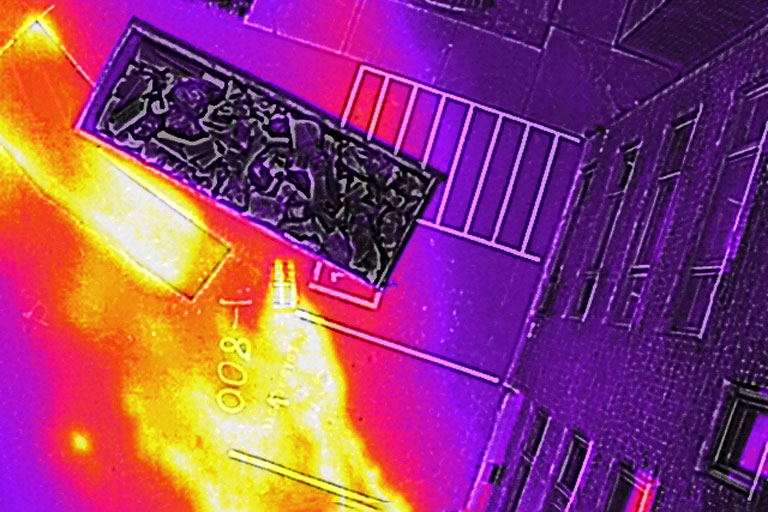

Drones are a boon for surveying topography, inspecting structures, and predicting how wildfires will spread or whether a roadside slope is stable. With a high-resolution thermal camera on board, drones are ideal for identifying steam leaks without unnecessary disruptive digging.

Graduate student Amirsalar “Saul” Moslehy started work at the institute in 2018 and earned his pilot’s license after Alshibli secured funding to purchase two drones. “Each drone has certain capabilities that make it suitable for different job sites or projects,” Moslehy said. He helped determine which drone and what type of thermal camera best fit the steam line project’s requirements.

Moslehy then mapped out 170 missions for the drone to fly over the steam lines. “It had to be at just the right height and angle. Every time I modified a parameter, I had to test it,” he said. After numerous test flights, the final flight paths resulted in the exact thermal and visual images the institute needed.

Knoxville’s volatile springtime weather was a challenge to work around. The institute team couldn’t fly the drone in rain, but they also didn’t fly when it was hot and sunny. “We needed the temperature difference between the steam lines and the adjacent area,” Moslehy said. “When the pavement heated up, we couldn’t see that difference in the thermal images.”

Early morning was the prime time to fly. It was cooler, and fewer students were out and about.

“UT is a no-drone zone,” Moslehy said. “I coordinated with many different departments to get permission to close sidewalks, fly the drone, and ensure we were all on the same page. When students were walking between classes, we paused our work.” He credits this role with helping develop his collaboration and project management skills.

In total, Moslehy and Alshibli compared the temperatures between almost 15,000 thermal images. “Once you find spots that don’t follow a regular heat escape pattern, you find the potential leak,” Moslehy explained.

Once the team mapped the problem spots, the results unexpectedly revealed that the performance of previous pipe repairs correlated with the type of thermal insulation used. By selecting a certain type of insulation, Facilities Services can make more effective repairs in the future.

This successful project has built a foundation for the institute to apply for new work on and off campus. And with future projects come new opportunities for graduate students to gain hands-on experience.

“Through the institute, grad students can acquire skills in an area that has a huge growth potential,” Alshibli said. “They may even learn how to start their own drone-based companies.” For him, that prospect is even more exciting than connecting with the local engineering community.