Keeping Cities Informed About E-Scooters

Thanks to a study led by Professor Chris Cherry and graduate student Nitesh Shah of CEE, city managers and policymakers will for the first time have data to make long-term decisions about the use and safety of e-scooters.

They scrutinized police reports of 52 e-scooter and 79 bicycle crashes with cars in Nashville between April 2018 and April 2020, finding a similarity

between crashes involving a motor vehicle and e-scooter with those involving a motor vehicle and bicycle: one in 10 leads to an injury or fatality for the e-scooter rider or bicyclist.

More than half of scooter crashes with vehicles came as the scooters left sidewalks at driveways and crosswalks, about twice the rate of such crashes for bicyclists. Their study also found that most scooter and bicycle riders are locals riding close to home, and most drivers live outside the city center.

The results suggest that a generalized approach for e-scooter and bicycle safety might not be the most effective and that policies and safety campaigns might have more impact with specific targeting.

Getting Stronger by Going Smaller

Scientists led by UT-ORNL Governor’s Chair for Advanced Alloy Theory and Development Easo George in MSE found a way to simultaneously increase the strength and ductility of an alloy by introducing tiny precipitates into its matrix and tuning their size and spacing. The precipitates are solids that separate from the metal mixture as the alloy cools.

Ductility is a measure of a material’s ability to undergo permanent deformation without breaking. It determines, among other things, how much a material can elongate before fracturing and whether that fracturing will be graceful or catastrophic. The higher the strength and ductility, the tougher the material.

If structural materials could become stronger and more ductile, components of cars, planes, power plants, buildings, and bridges could be built using less material. Vehicles that weigh less would be more energy efficient to make and operate, and tougher infrastructure would be more resilient. The results, published in the journal Nature, will open new avenues for advancing structural materials.

Moving the Navy Forward

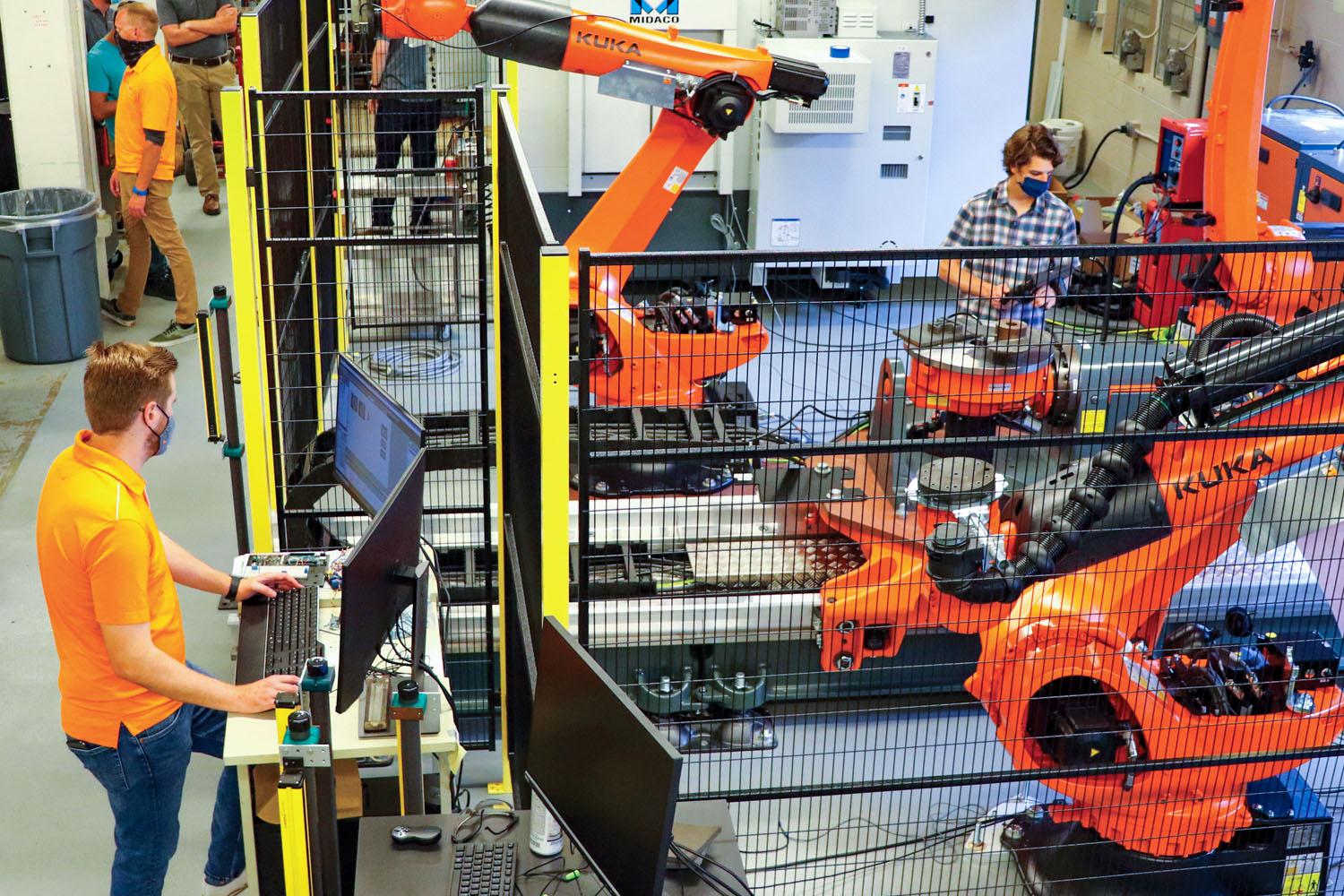

The fabrication of large, complex metallic structures, especially at the point of use, is a persistent challenge for the US Navy. Emerging hybrid manufacturing—which combines additive and subtractive manufacturing—offers important opportunities to address these challenges.

Professors Bill Hamel and Tony Schmitz and Associate Professor Bradley Jared, all of MABE, are addressing those issues in a new two-year, $1.825 million research project, with the objective of achieving integrated and iterative hybrid manufacturing of large metal parts involving multiple alloys.

The project, part of a larger Office of Naval Research effort, also includes the creation of a unique state-of-the-art large-scale hybrid metal manufacturing research testbed in the Nathan W. Dougherty Engineering Building, with the ultimate goal of developing an automated workflow that can be reproduced in the field. Structured light scanning will create digital image representations that will allow parts to be moved back and forth between printing and machining while maintaining dimensional accuracy.

Looking at the Future of Artificial Intelligence

Under the direction of Congress, the National Science Foundation and the White House Office of Science and Technology Policy created the National Artificial Intelligence Research Resource Task Force, a 12-person group that includes Professor Lynne Parker as co-chair and Professor Emeritus Mark Dean, both in EECS.

The National AI Initiative Act of 2020 mandated the formation of the group with a goal of providing guidance for increased access to computational resources, high-quality data, educational tools, and user support for AI researchers and students across all scientific disciplines. The task force recommendations will include technical capabilities, governance, administration, assessment, and requirements for security, privacy, civil rights, and civil liberties.

The group is to deliver a report on initial findings in May 2022, with a final report the following November. Those results will help provide dividends in both research and workforce development, guiding AI policy and best practices for the future.

International Modeling Helps Improve Small Modular Reactors

Small Modular Reactors, or SMRs, are expected to play an important role in the near-term nuclear energy deployment mix and promise to offer several advantages in comparison to large-scale nuclear reactors, including safety benefits.

Research Assistant Professor Ondrej Chvala and Professor Ivan Maldonado, both of NE, recruited Pavel Suk, an International Atomic Energy Agency–funded visiting research scholar from Czech Technical University, for collaboration surrounding SMR advancements. Together they employed a state-of-the-art modeling and simulation tool and applied it to a representative model of the NuScale reactor, which is a leading concept among next-generation SMRs.

The research team used an advanced simulation package for analyzing light water reactors developed by the Consortium for Advanced Simulation of Light Water Reactors at ORNL. The computer code, VERA (Virtual Environment for Reactor Analysis), aims to apply and deploy advanced science-based technologies to enhance the operational performance, efficiency, safety, reliability, and economic competitiveness of light water reactors.

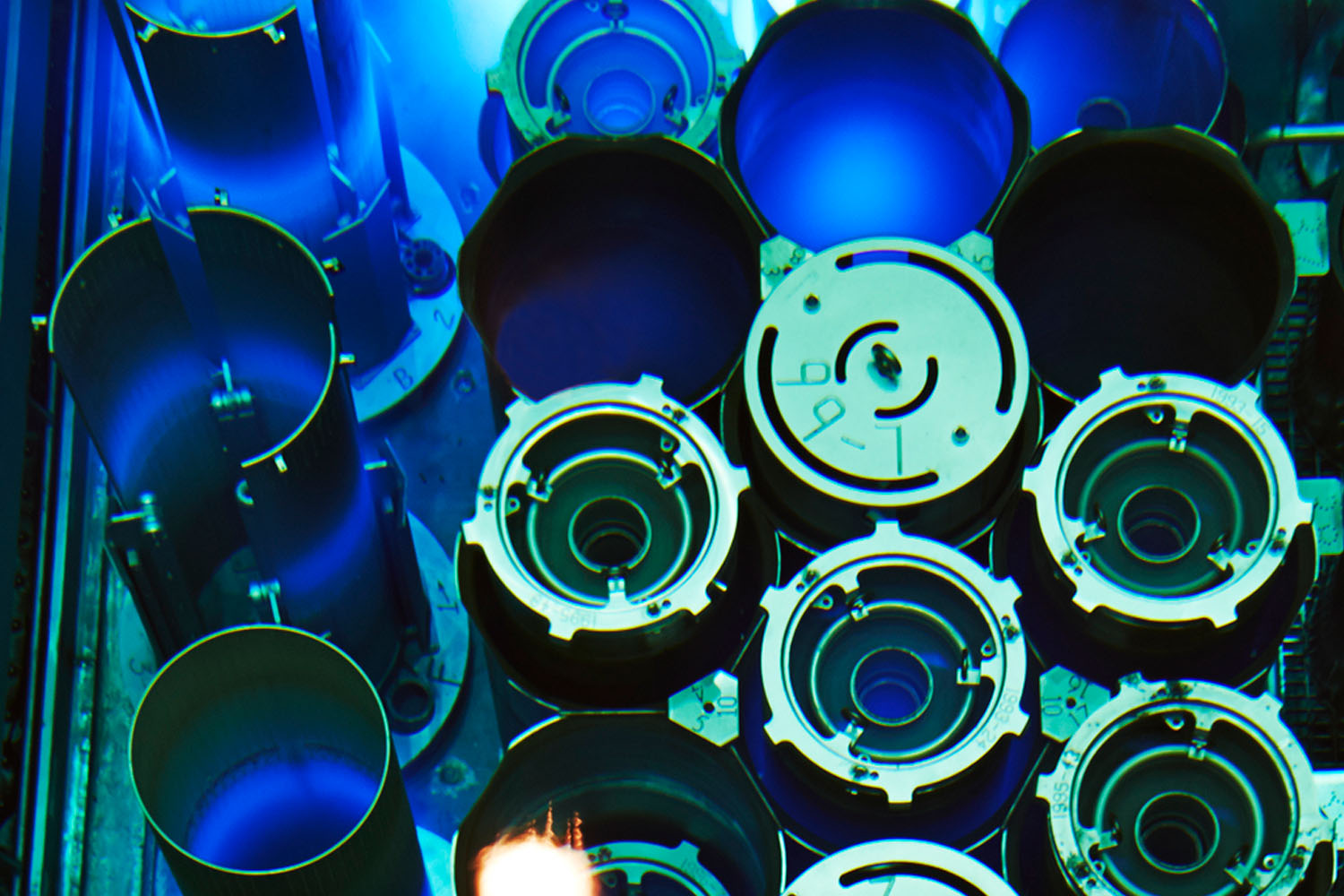

Laying the Groundwork for Space Travel

Space exploration brings to mind images of rockets soaring out of Earth’s atmosphere, but nothing takes off without a plan on the ground. That’s where Professor Andrew Yu, of ISE and UTSI, helps by sharing his expertise on facility and asset maintenance planning and prioritization to minimize mission risk.

Yu maintains strong collaborations with industry partners, giving him opportunities to work on and solve real-world problems. His work is of particular importance in helping prioritize maintenance tasks for mission-critical facilities as well as identifying and weeding out counterfeit electronic components.

In the long term, Yu hopes to apply different theories to help aerospace-related industry solve supply problems and provide solutions that can be used on a daily basis. As director of UT’s distance-learning Engineering Management program, Yu also helps practicing engineers—many of them working in aerospace industries or with the military—earn graduate certificates and master’s and doctoral degrees.