By Rhiannon Potkey. Photography by Shawn Poynter.

For the last 230 years, the University of Tennessee has provided a short-term home for students where they can learn, grow, and experiment until they are ready to leave campus and launch enriching professional careers.

The Tickle College of Engineering wants to create a similar environment for startup companies, and now has a facility to make it happen.

The TeNnessee MAnufacturing and Design Enterprise (TN-MADE) facility in Hardin Valley is one of the programmatic and physical manifestations of the Manufacturing Innovation Initiative (MI2), an initiative launched by the Institute of Advanced Materials and Manufacturing (IAMM) at UT.

The facility, which is ideally located in the heart of Knoxville’s burgeoning technology innovation district, is specifically focused on advancing hybrid manufacturing processes incorporating both additive and subtractive methodologies.

UT aspires for the facility to become an incubator for startup companies, providing a foundation for them to flourish, move into the market, and eventually graduate into their own facility, creating a manufacturing innovation center that grows East Tennessee’s economy.

Many startups don’t have the resources they need in the early stages and struggle to fulfill the potential of their ideas and creations. TN-MADE can give them access to not only cutting-edge machines, tools, and space, but to UT faculty and students in a mutually beneficial and cost-efficient partnership.

TN-MADE offers 48,000 square feet of high bay research space, a large lecture location, office space, and a large foyer perfectly suited to host meetings and events that support the regional manufacturing mission.

“That is so important, because you see so many young entrepreneurs doing really good things, but they aren’t provided with some of those gap capabilities and they end up moving to other markets,” said Marc Gibson, UT’s associate vice chancellor of partnerships and economic development. “We are trying to reduce the risk of them leaving the state. We want to develop a robust cluster of manufacturing companies and startups here in East Tennessee and grow the jobs of the future that will have a lasting impact on our economy.”

Taking technology all the way to the top

TN-MADE complements other IAMM MI2 programs and facilities supporting manufacturing-focused innovation, such as Innovation South at the UT Research Park at Cherokee Farm. However, unlike projects at other IAMM MI2 facilities, which are limited to research and development, TN-MADE can support production of commercial products.

“This building is going to back small-scale production and the ability to prototype in this space,” Gibson said. “It gives us such a huge leg up because we can take the technology to a much farther scale and take it all the way to the top.”

MABE Professor and ORNL Joint Faculty Tony Schmitz is the anchor tenant at TN-MADE as the director of the Machine Tool Research Center. During the first year of the MTRC location at TN-MADE, the facility has hosted more than 1,000 visitors.

Key partners in research and training have included Oak Ridge National Laboratory’s Manufacturing Demonstration Facility, DEVCOM Army Research Laboratory, the NSF Engineering Research Center HAMMER, the Defense Manufacturing Community Support Program Southeastern Advanced Machine Tools Network, DoD’s Industrial Base Analysis and Sustainment program, MSC Industrial Supply, Y-12 National Security Complex, and the Gene Haas Foundation.

“The opportunity to locate my laboratory, MTRC, at TN-MADE has been transformational,” Schmitz said. “It has afforded me the rare opportunity to co-locate teaching, training, and research capabilities in a state-of-the-art facility.”

Developing an innovative workforce

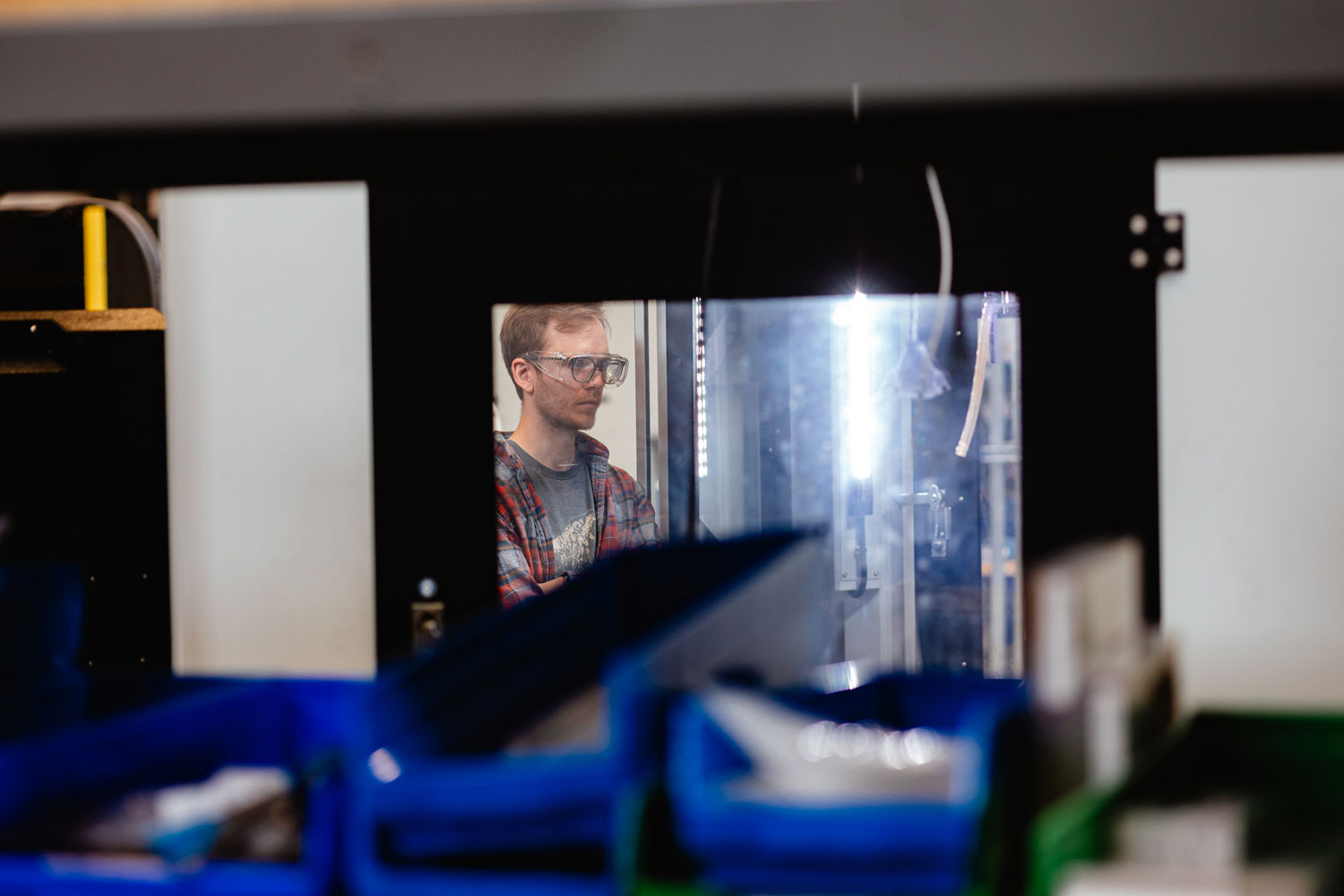

Tyler Woodard, a PhD student in mechanical engineering, has been working in robotics at TN-MADE for the last year. The facility has given him access to everything he needs in one location.

“It gives me a lot of hands-on experience that I just didn’t have the opportunity for in my undergraduate work,” Woodard said. “There is just a lot more here to do every day that has been a huge benefit for me. It makes everything a lot more seamless.”

As the college grows, TN-MADE will remain an integral piece of the strategic plan to give TCE students a well-rounded educational experience that prepares them for the industry. Beginning in 2025, the new Department of Applied Engineering and Technology will hold classes at TN-MADE.

“Students will have access to the advanced manufacturing machines and faculty we have there,” said Dean Matthew Mench, the Wayne T. Davis Dean’s Chair of the college. “TN-MADE gives our college a unique capability and unique expertise. Most schools have the $1,500 3D plastic printers and we have state-of-the art manufacturing technology.”

There will likely be a time in the future when UT students who launch startups find a home at TN-MADE, or startup companies that utilize space at TN-MADE will hire UT students as they grow. Being able to foster those relationships will only make UT more competitive in the manufacturing ecosystem.

“The TN-MADE business model needs to be attractive to business. It’s important for the university to be cutting-edge in our partnership approach with the private sector,” Gibson said. “Our business model will provide agility, adequate space, and access to people and equipment within our ecosystem. And perhaps, most important, we must move at the speed of business and think like a business.”