A long tradition of Volunteer involvement comes around full circle for Knoxville manufacturer Fulton Bellows through an ongoing membership with the Center for Materials Processing (CMP). The company was founded in 1902 by UT meteorologist Weston Fulton, and now engages with the CMP by placing UT materials science and engineering (MSE) students at the cutting edge of developing better materials.

Fulton shares an industry-wide challenge to develop new products in the areas of aerospace, automotive, and oil and gas. These are rarely designed with old technologies, so the CMP student program helps Fulton connect with the latest materials, processes, characterization instrumentation, and modeling and databases.

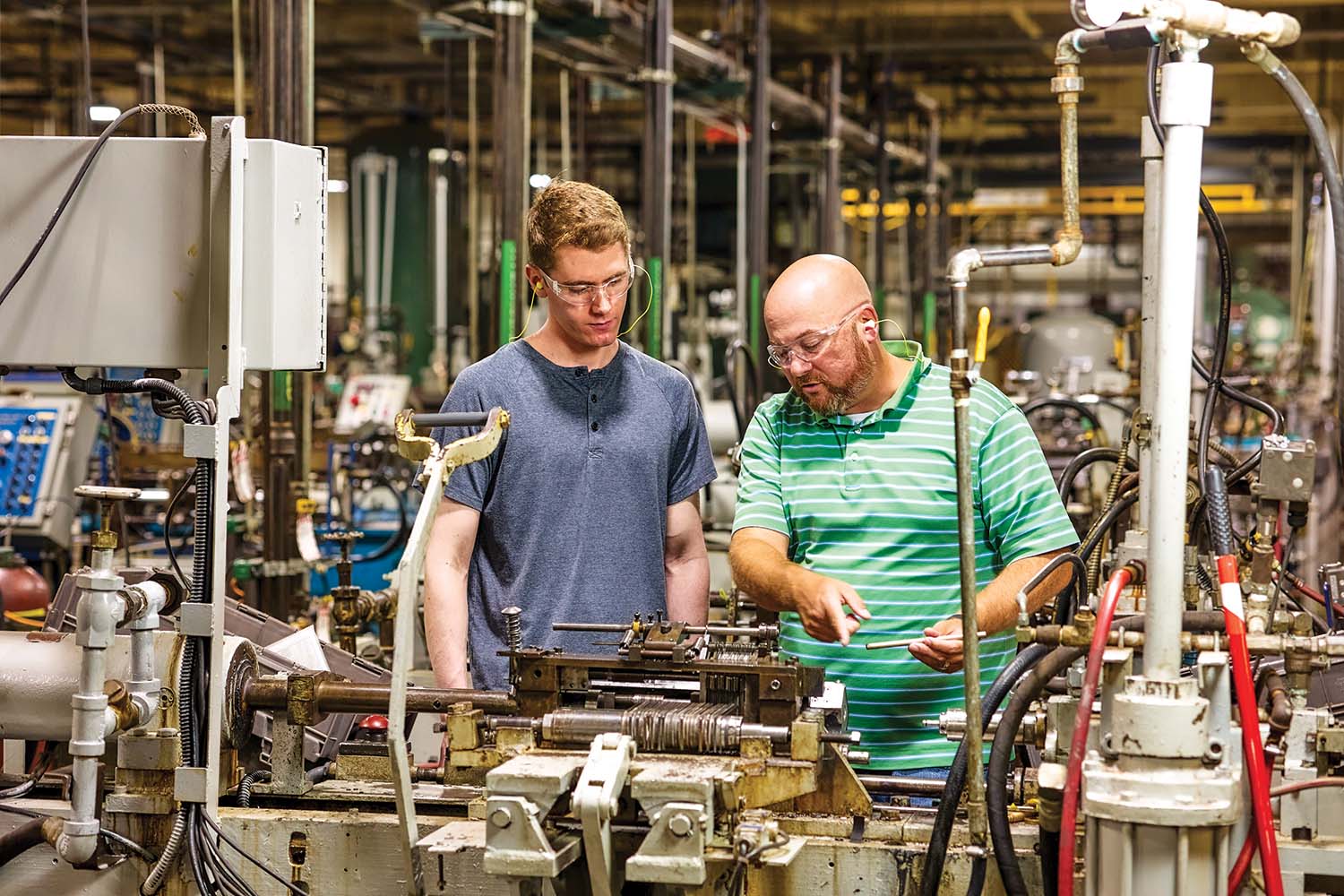

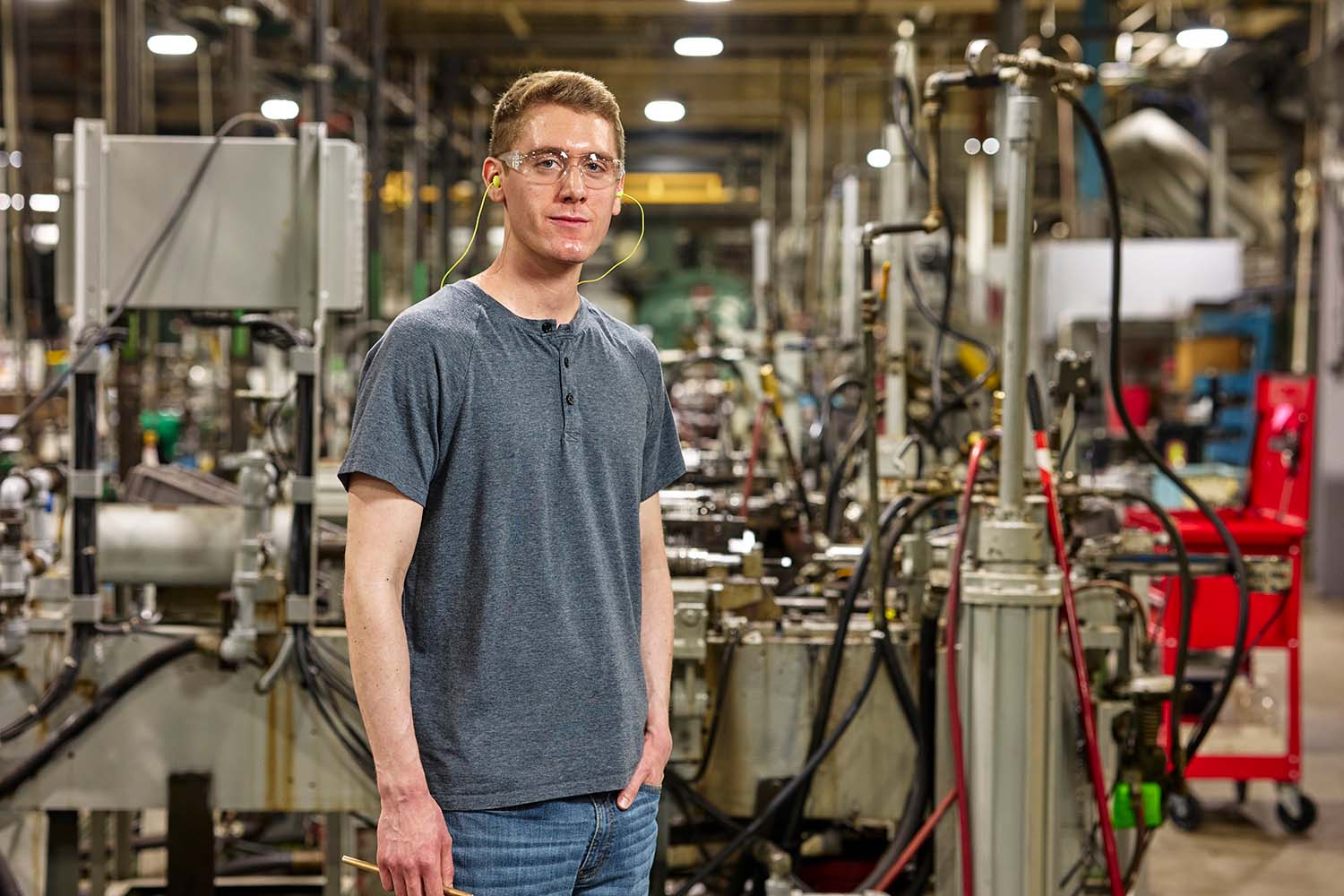

Cole Franz, a five-year BS/MS student in MSE, has been the primary student working with Fulton since 2020. His first order of business when he is on-site is to listen and gather information from the people who make the facility work.

“At every level of Fulton’s operation, the people, the machinery, and the processes come together essentially as puzzle pieces,” said Franz. “Together, with the scientific knowledge that my mentors have taught and graciously provided to me, I utilize this information to help solve problems.”

“Cole has performed above and beyond any expectations that Fulton could have imagined,” said Kelly Ferguson, manufacturing engineer manager at Fulton. “He has been very instrumental in helping us identify issues and then developing solutions to overcome.”

In return, Franz is able to apply these lessons when he is back in the classroom.

“Due to the nature of the analyses, my understanding and use of equipment that is vital to the materials scientist has improved,” he said.

“On multiple occasions, Cole has also prepared and presented findings to a high-level customer of Fulton,” added Ferguson. “We could not have asked for more.”

The processes at Fulton Bellows transform metals—often exotic metals—from sheet or coil into thin-wall tubes, which then is formed into bellows for assembly applications.

“Often times, our processes will push the material to the extreme limits of its performance,” said Ferguson. “Cole has been working with us to identify adjustments to our process to avoid these boundaries so that we can keep material properties more uniform and predictable. Our business is all about consistency – if we have a consistent process, we can adjust accordingly to overcome issues that arise. Through the partnership with the CMP, we are able to normalize our processes and provide a more consistent product.”

Assistant Professor Eric Lass, the faculty point-person for students and Fulton, feels that the relationship has given him an industrial perspective of day-to-day issues related to engineering, and increased knowledge of the expectations for entry-level engineering graduates.

“I believe that the MSE department as a whole can greatly benefit from an improved understanding of industrial needs, better preparing our students for their careers,” said Lass. “We are also planning to have a capstone, senior design project sponsored by Fulton this upcoming academic year, which will provide our seniors first-hand experience into real-world industry-related problems.”

For Franz, the exercises in technical communication revitalized his interest in how engineering problems are solved.

“At every level of Fulton’s operation, the people, the machinery, and the processes come together essentially as puzzle pieces. Together, with the scientific knowledge that my mentors have taught and graciously provided to me, I utilize this information to help solve problems.”

—Cole Franz

“No matter anyone’s role or responsibility, everyone has critical information and unique perspectives to contribute to the optimal solution,” he said.

“I’ve realized that no one person can be responsible for or can solve complex problems. It requires a team.”

A new CMP student, rising junior Jack Frederick, joined the program for summer 2021. He will participate in a deep dive of multiple materials projects for product lines as Fulton addresses a spike in demand with the return of certain markets after 2020’s downturn.

“These students are already getting prepared to be ready for identifying opportunities to improve our processes which will ultimately result in reduced scrap costs and improved yield,” said Ferguson. “This will allow Fulton Bellows to be more competitive in a very demanding market, with the goal being improved quality, increased market share, and sustainability for our business.”