By Izzie Gall. Photography by Shawn Poynter.

Canadarm2, a robotic arm on the outside of the International Space Station, is 13.8 inches thick and made of 19 layers of high-strength carbon thermoplastic. In 2021 a grain of dust moving at more than 15,000 miles an hour punched a hole straight through it.

“A high-velocity impact creates stress waves that ripple throughout a material,” explained Suresh Babu, UT–Oak Ridge National Laboratory Governor’s Chair for Advanced Manufacturing. “If the material cannot take the stress, it fractures.”

Though this kind of event may last only an instant, the power behind it is enough to blast the ends of a sesame seed more than six miles apart in a single second—and that power applies incredible stress to every sesame seed–sized particle at an impact site.

When a material like metal suffers this kind of impact, the resulting breakage is called spall damage.

We train our students to ask foundational questions rather than just accepting an untested consensus. It’s what we are known for, and we are good at it—as Dr. Lamb has demonstrated.”

“Spall can also result from car crashes and detonation blasts,” said Kevin Lamb, a senior materials research technician at the Y-12 National Security Complex and one of Babu’s former PhD students.

Traditionally, materials like car bodies and spaceship hulls have been made from wrought materials, which are heated until they become liquid, poured into a mold, and cooled. This process makes them internally consistent and solid, which intuitively seems like an advantage against impacts—would you rather jump on a plank made of hardwood or one of cork?

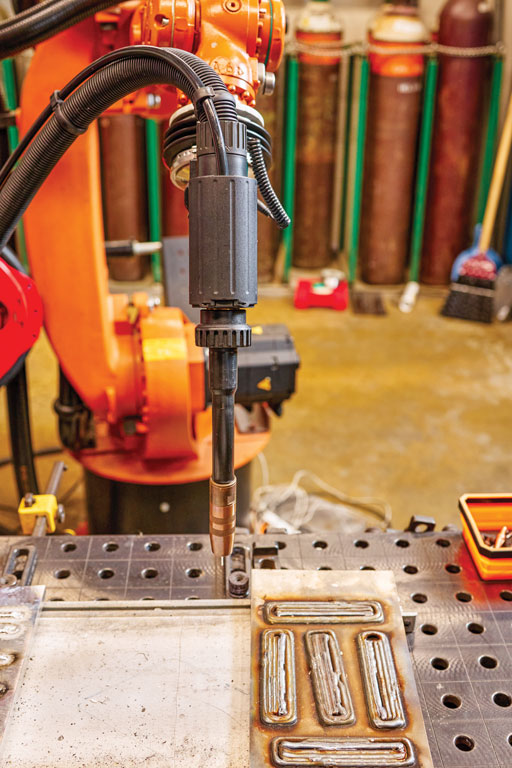

Babu and Lamb recently started to wonder, however, whether additively manufactured materials—that is, 3D-printed ones— may be better at resisting spall.

The idea might seem surprising. AM materials are created from one end to the other, one thin layer at a time, so they are inherently stronger in some directions than others. If the bonding between layers is imperfect, the finished material can include lots of tiny gaps.

“These inconsistencies in AM materials are sometimes considered undesirable,” said Lamb. “However, if we purposefully engineer those variations, we might be able to control the flow of stress waves within an otherwise solid structure.”

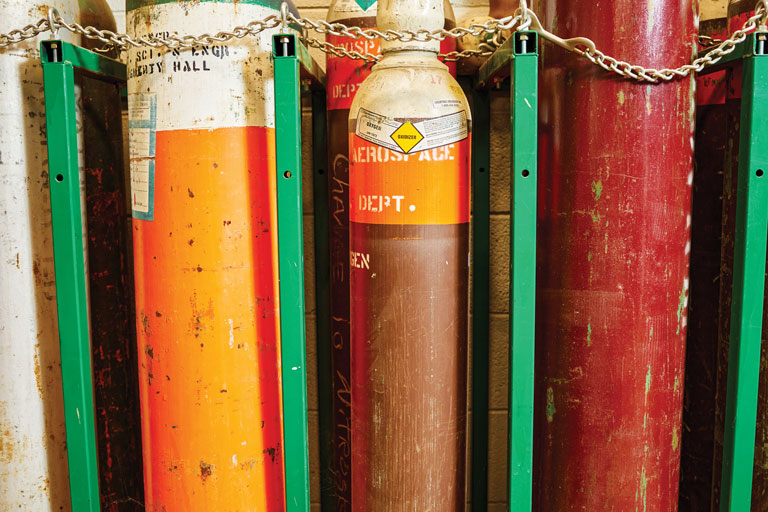

To investigate this idea, Lamb and Babu additively manufactured samples of 316L stainless steel, a material commonly used in marine and architectural applications, in two different build directions. Through a partnership with Georgia Tech’s High-Strain Rate Laboratory, they fired iron discs out of a gas gun at 560 miles an hour, striking each AM sample and a wrought control sample. Instruments embedded in the samples provided detailed information on how each sample fared—down to millionths of a second.

The AM samples took more stress than the wrought sample before deforming and endured less overall damage from the impact. Lamb was more excited, however, by the discovery that the AM samples were most durable when the impact was perpendicular to their build direction.

“This means we can change where an AM material will be damaged, and how badly, by considering the direction of expected impact when we design it,” he said.

Additive manufacturing is a promising technique because it can be used to create complex structures that are difficult and expensive to create from wrought materials, but the stress tolerance of those pieces has been a persistent worry.

By challenging what seemed to be an obvious inference, Lamb and Babu have demonstrated that those parts can be manufactured at low cost without sacrificing reliability.

“That is something unique about UT,” Babu reflected. “We train our students to ask foundational questions rather than just accepting an untested consensus. It’s what we are known for, and we are good at it—as Dr. Lamb has demonstrated.”